Manufacturing

Low-strength coupling nuts are most frequently manufactured from AISI 1018 hex bar or round bar. High-strength coupling nuts are manufactured from AISI 1045 or 4140 steel and undergo a heat-treating process. Stainless steel coupling nuts are most frequently manufactured from AISI Type 304 or 316 stainless steel.

Equipment

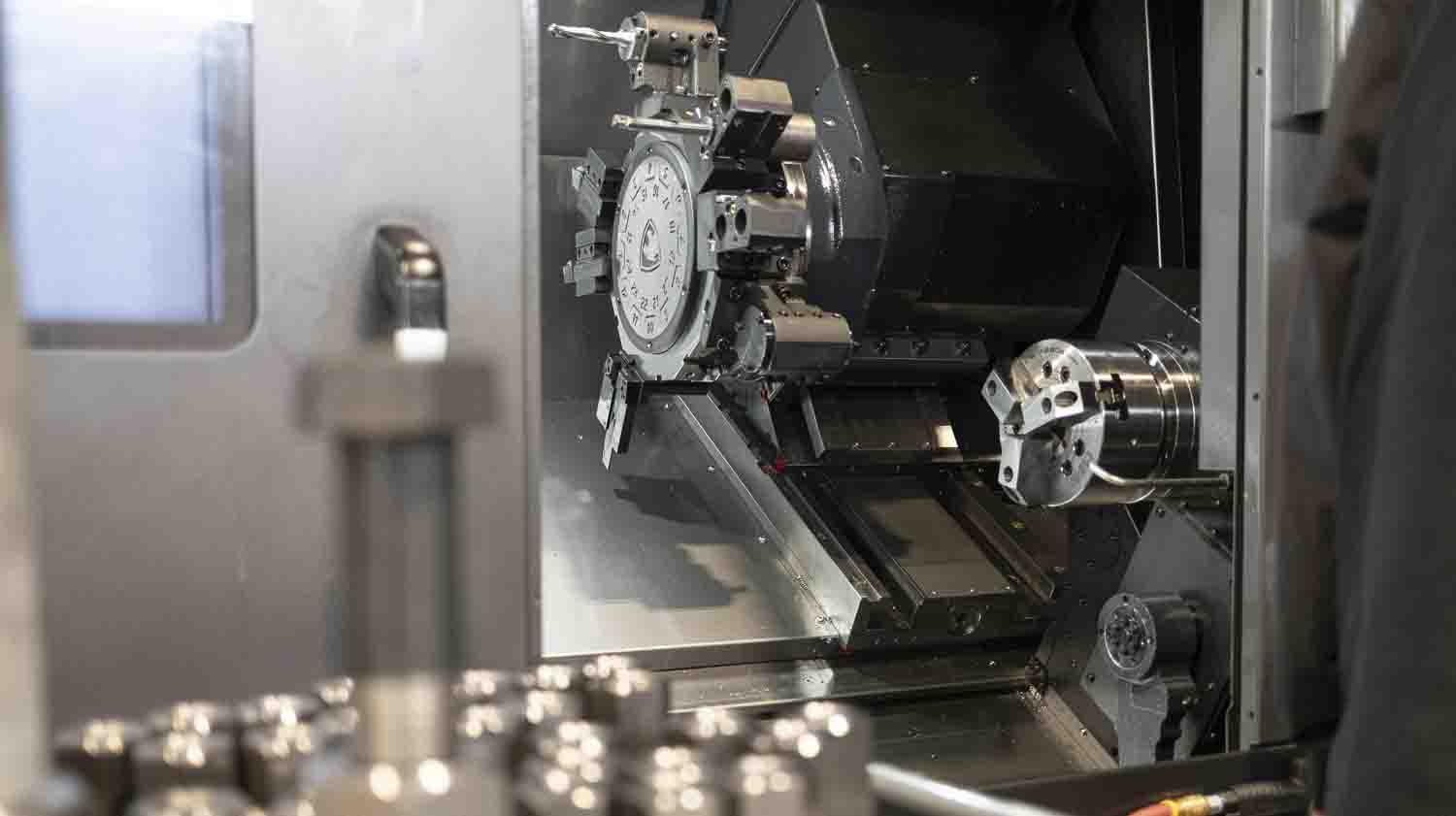

A CNC lathe is a machine tool that uses computer numerical control (CNC) to rotate a piece of material around a central spindle. This allows a cutting tool to remove material and create precise, usually cylindrical parts by following coded instructions fed into the computer rather than being manually operated.

Cutting

Coupling nuts are cut from 12’ bars of hexagonal steel on the CNC lathe. Parts can also be cut on a band saw or cold saw.

Facing

The CNC lathe faces the ends of the coupling nuts, providing the finished flat and beveled ends.

Marking

High-strength coupling nuts require a manufacturer’s identifier and the grade symbol to be permanently marked on one face of the coupling nut. Low-strength couplers require no markings.

Drilling

The CNC lathe drills a center hole down the length of the hexagonal or round coupling nut.

Tapping

The CNC lathe taps the internal threads of the coupling nut. Couplers that are 2-1/4” in thread size and smaller are typically threaded all the way through, while larger diameter coupling nuts are threaded in from each end.

Sight Hole (Optional)

Optional sight holes are drilled through one face of the coupling nut by the CNC lathe at the center point to ensure that each threaded fastener is fully engaged.

At Portland Bolt, manufacturing quality is built into every step of the process. From raw material selection to final inspection, Portland Bolt maintains strict internal controls to ensure consistency, traceability, and performance in every fastener produced. Our in-house manufacturing capabilities allow for tighter tolerances, faster turnaround times, and direct oversight of critical processes, reducing variability and risk for our customers. By combining experienced craftspeople, modern equipment, and rigorous quality standards, Portland Bolt delivers custom fasteners that meet demanding specifications and perform reliably in the field.